CALCIUM CARBONATE

PERO MINERAL Calcium Carbonate grades are branded as CALCARB® in general, let end users to produce high quality products in many applications.

Calcite (CaCO³) found in nature in marble, limestone and chalk forms with different crystal shapes. Depending on the amount of impurities, whiteness parameters may fluctuate. Deviation of Silicate (SiO² ) contents will also effect hardness values of the material.

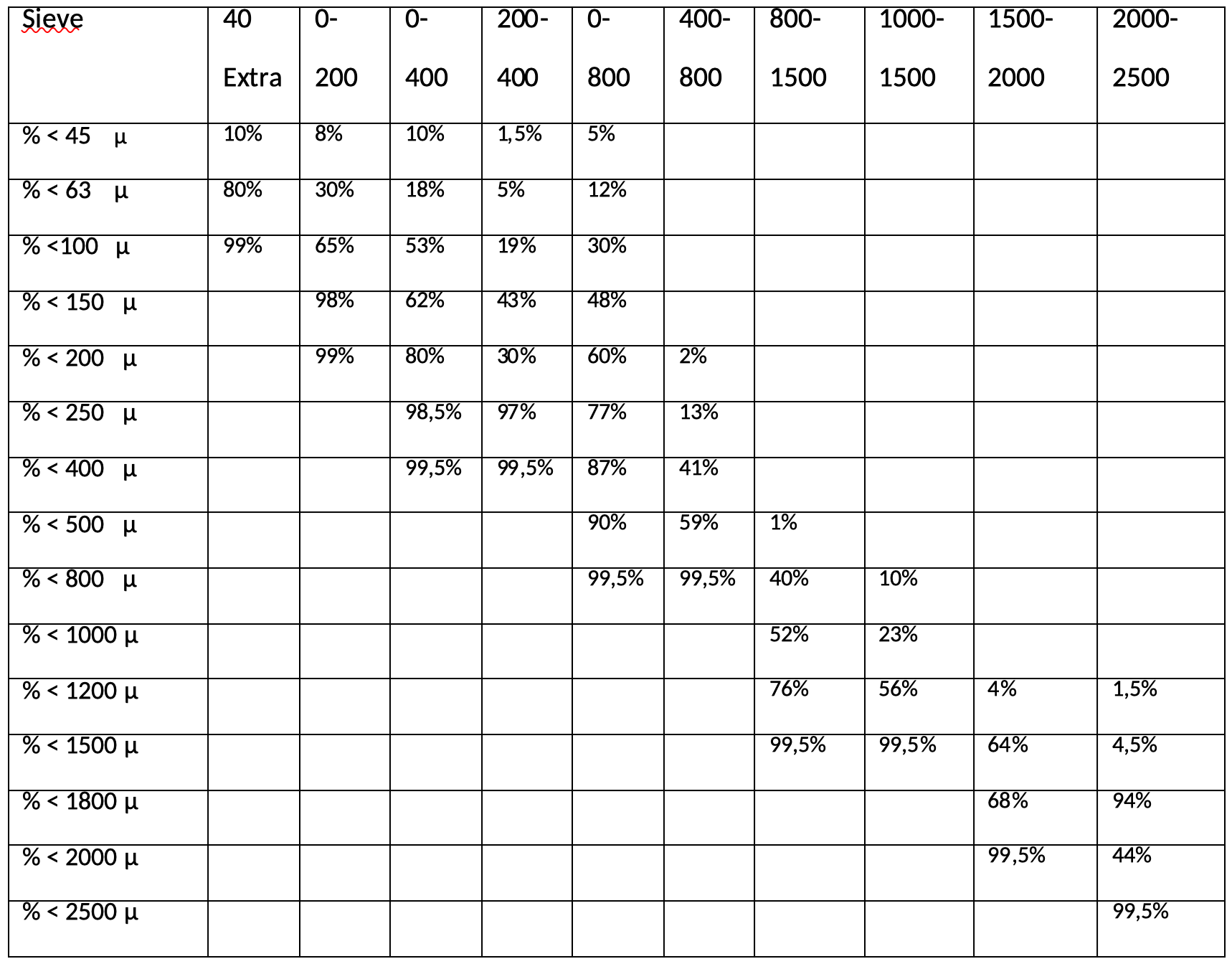

CALCARB® high brigthness and negligible abrasion values features the quality of CALCARB raw material quality level. CALCARB® grades are very fine GCC (Ground Calcium Carbonate) which is also featured with fine particle size distribution. Starting from 90% fraction under 2 microns fineness till 100 microns median size, PERO MINERAL able to produce outstanding products to offer optimum solutions. Ultrafine grades of CALCARB® will offer superior surface finish solutions to paint, paper and plastics industries.

Overseparated CALCARB® grades are another class of product group in which surface coating is not feasible, to decrease the oil absorption values. Decreasing the oil absorption of calcium carbonate will bring so many advantages to processors to decrease binder absorption, decreasing of manufacturing costs while using more calcium carbonate in the recipes.

CALCARB® UF

CALCARB® 95

CALCARB® 75X

CALCARB® 65

CALCARB® 1

CALCARB® 1K

CALCARB® 2

CALCARB® 2K

CALCARB® 2X

CALCARB® 3

CALCARB® 5

CALCARB® 5K

CALCARB® 10

CALCARB® 15

CALCARB® 15K

CALCARB® 20

CALCARB® 40K

CALCARB® 60K

CALCARB® 130K

Usage of Coated CALCARB® grades have many advantages in plastics and coating.

Day by day, more these processors are shifting to coated grades due to;

Low surface energy,

High Hydrophobic effect,

To get easy and homogenious dispersion,

Low oil, DOP and polymer absorption,

Increase in mechanical properties.

Increase chemical and mechanical strength,

To get high quality surface and high brightness,

CALCARB® UFC has same particle shape characteristics as CALCARB® UF, whereas it’s surface treated with suitable hydrofobic agents which enables to keep high gloss values in solvent based paints during long period of time. Since surface treatment changes alkalinity of natural Calcium Carbonate, it also keeps oil acids in alkyd resins away from Calcium Carbonate surface. If this contact occurs, Calcium carbonate reacts with acids to form CO² gas, that forms bubbles which create matting in paint film during storage on shelves after production.

The FILMFORM range of fine coated calcium carbonates are the leading mineral product in breathable film applications for the hygiene, medical and roofing markets.

CALCARB® UFC, CALCARB® 100C and CALCARB® 95C goods which are especially prefered in plastic profile sector and has low abrasivity of extruders with good surface.

CALCARB® CGR grades can be used in wide range of applications like exterior decorative coatings, plasters and texterud coatings. Particle distribution and colour parameters of CGR and GRN grades are so adjusted that, they can meet demands of global common recipes.

CALCARB® UFC

CALCARB® 95C

CALCARB® 75C

CALCARB® 65C

CALCARB® 1C

CALCARB® 1XC

CALCARB® 2C

CALCARB® 2XC

CALCARB® 3C

Low binder absorption

Dust free productions

Homogenous particle distribution

Black spot free products

High production capacity

Controlled tinting capability

High and long lasting brightness

Excellent optical effect and opacity

High brightness

Dust free products

Acid resistance

- Homogenous particle distribution

- Black spot free products

High production capacity

Controlled tinting capability

Perfect durability in exterior applications

CALCARB® CGR G130

CALCARB® CGR H130

CALCARB® CGR 0105

CALCARB® CGR 0208

CALCARB® CGR 0305

CALCARB® CGR 0307

CALCARB® CGR 0512

CALCARB® CGR 1.0-1.5

CALCARB® CGR 1.5-2.0

CALCARB® CGR 2.0-2.5

CALCARB® CGR 2.5-3.0

CALCARB® CGR 3.0-3.5